EcoBlaze Chainsaw

WHAT IT DOES

The EcoBlaze chainsaw enables California wildland firefighters to continue their life-saving work whilst forwarding the sustainability movement by minimizing the use of fossil fuels.

INSPIRATION

To help our planet and its inhabitants, we need to limit our use of fossil fuels. This can only be enabled by advances in renewable technologies. At the beginning of 2024, California placed a ban on the sale of spark-ignition internal combustion engines under twenty-five horsepower.

Finding a viable alternative to the gas-powered chainsaws currently used in wildland firefighting is an immediate and critical need. Wildfires in California have become increasingly devastating to the point that sustainable and effective tools for their suppression are imperative. The goal of the EcoBlaze is to fulfill the requirements of a severe-duty firefighting tool while avoiding the use of an internal combustion engine.

HOW IT WORKS

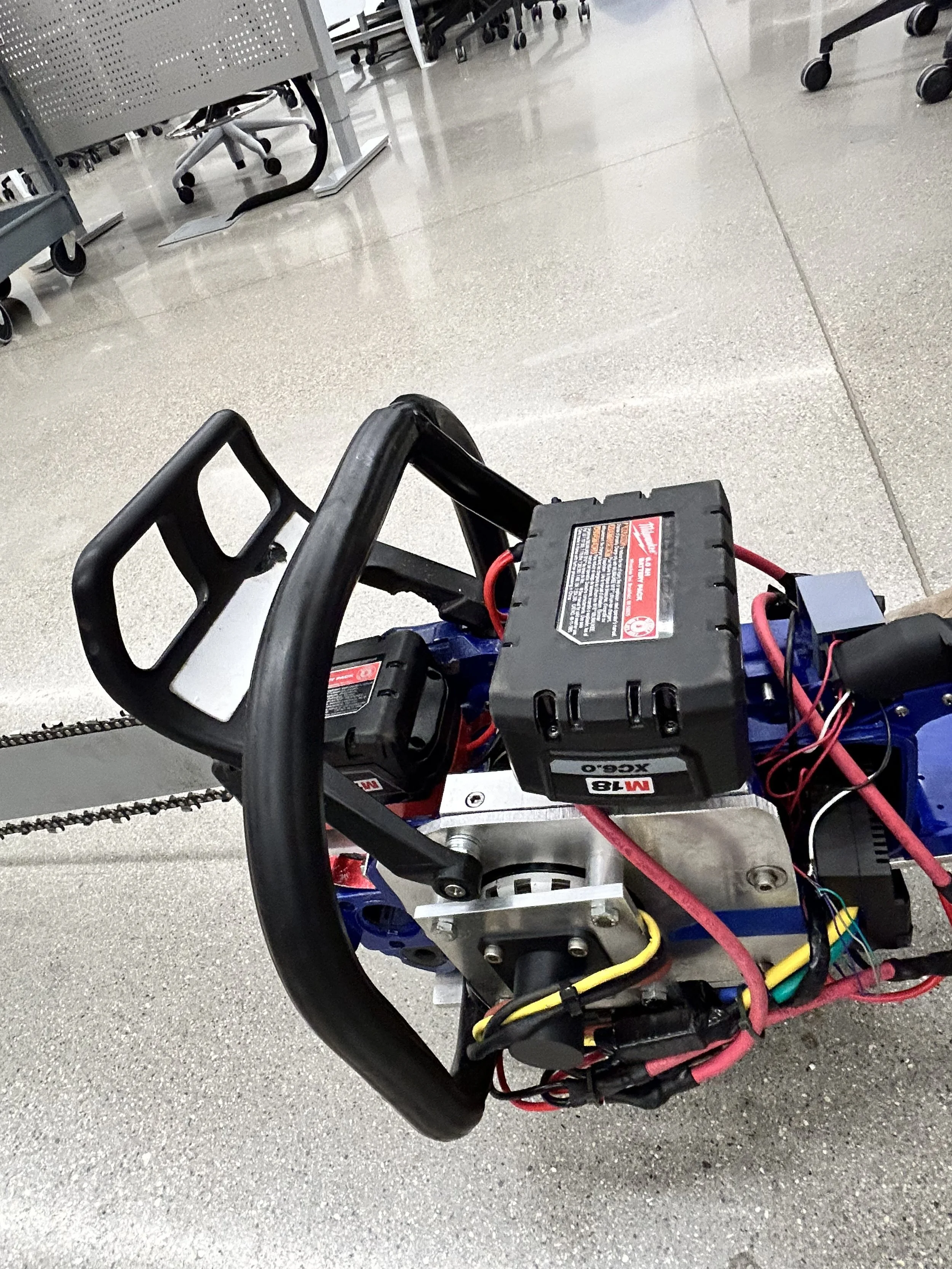

The EcoBlaze uses a commercially available electric motor and up to six Milwaukee M18 batteries to produce a rated power output of up to 9.4hp (7kW). When compared to the standard gas-powered Stihl MS-440’s 5.4hp (4kW), commonly used in firefighting, and the battery-powered Stihl MSA-300 C-O’s 4.0hp (3kW), the EcoBlaze provides ample cutting power for any situation.

DESIGN PROCESS

During the design process, we focused on understanding the needs of California wildland firefighters and chainsaw manufacturing companies. Our goal was simply to match the performance and usability of a gas-powered chainsaw whilst enabling the use of sustainable energy.

Our prototyping process began with selecting a chainsaw to redesign. For this, we chose the Stihl 660 because it is commonly used in wildland firefighting, would be familiar to firefighters, and has ample space to implement modifications. For the motor, we decided on an off-the-shelf motor built for an electric scooter because it had similar torque and speed ratings to the small engine it would be replacing.

We interviewed and tested our prototype on firefighters who were familiar with the tool and use case. Through feedback from several seasoned firefighters, we came to better understand the nuance and importance of the weight and balance of the machine. Firefighters currently carry a container full of gas and oil separate from their chainsaws. The modular nature of the EcoBlaze allows the user to carry its batteries conveniently during long-distance travel.

HOW IT IS DIFFERENT

Current battery technology does not have the energy density to supply sufficient power for a reasonable period of time without severely inhibiting the mobility and ergonomics of a chainsaw. Even though the future of battery technology holds promise for further improvement, the EcoBlaze has mitigated this issue through its modular design by allowing the user to vary the number of batteries based on immediate use case requirements.

Instead of balancing the pros and cons of power, weight, and run time, our team prioritized flexibility of use by pursuing a modular design. Current chainsaws have a set operating weight regardless of the use case. The EcoBlaze chainsaw allows the user to choose how many batteries to mount, based on their current needs, as well as adjust motor power via a linear slide. Additionally, the EcoBlaze can be powered from a standard 125V extension cord if the circumstance allows. This ability to alter run-time, weight, power output, and source based on situational requirements makes the EcoBlaze chainsaw a versatile and viable tool for severe duty uses such as wildland firefighting.

Another area in which our chainsaw stands out from its gas-powered counterparts is the fact that it does not require “clean” combustion air to operate. Through our interview with a fire chief in California, we learned that gas chainsaws sometimes suffer performance loss when they are forced to operate in smoky environments. Our saw would be immune to this dilemma given its only constant resource requirement is energy from either batteries or a power cable.

FUTURE PLANS

Our next step will be to develop an auxiliary cooling system to prevent overheating regardless of extreme ambient temperatures. Once this is complete, we will move on to the development of custom encasement to more effectively prevent debris from entering the motor.

Looking to the future, we will continue to test our design with the people who it will one day serve, making it the best possible fit for their needs. Getting a finalized EcoBlaze into the hands of California wildland Firefighters, enabling them to help both the people and the planet.

Before this project, I felt uncomfortable modifying or attempting to invasively tinker with machines and electrical workings. Through this project I have gained experience and knowledge about how a machine such as a chainsaw works, so that I may feel confident working on pre-existing complicated systems in the future.

As this was my first time working on a larger team, I quickly learned that although my explicit job was to ensure the complex user needs of firefighters were met, there was more to it. It is much easier to get a group member out of their shell in a smaller setting. My secondary responsibility was that of creating a safe and inclusive environment in which everyone’s voice gets heard, so that we can build something we are all proud of.