The Lunch-Time Fun-time!

The Problem

During the fall of 2022 I had the opportunity to work with a team to design a toy for REACH Services—a children’s therapy clinic.

We discovered that children at REACH Services with impaired fine motor skills had trouble opening their lunch boxes and so had a need for engaging opportunities to practice using fasteners. REACH talked to us about how there are currently products aimed at solving this problem already, but they fail in the key aspect in that they are not fun, and therefore do not keep the child engaged and learning.

The Design

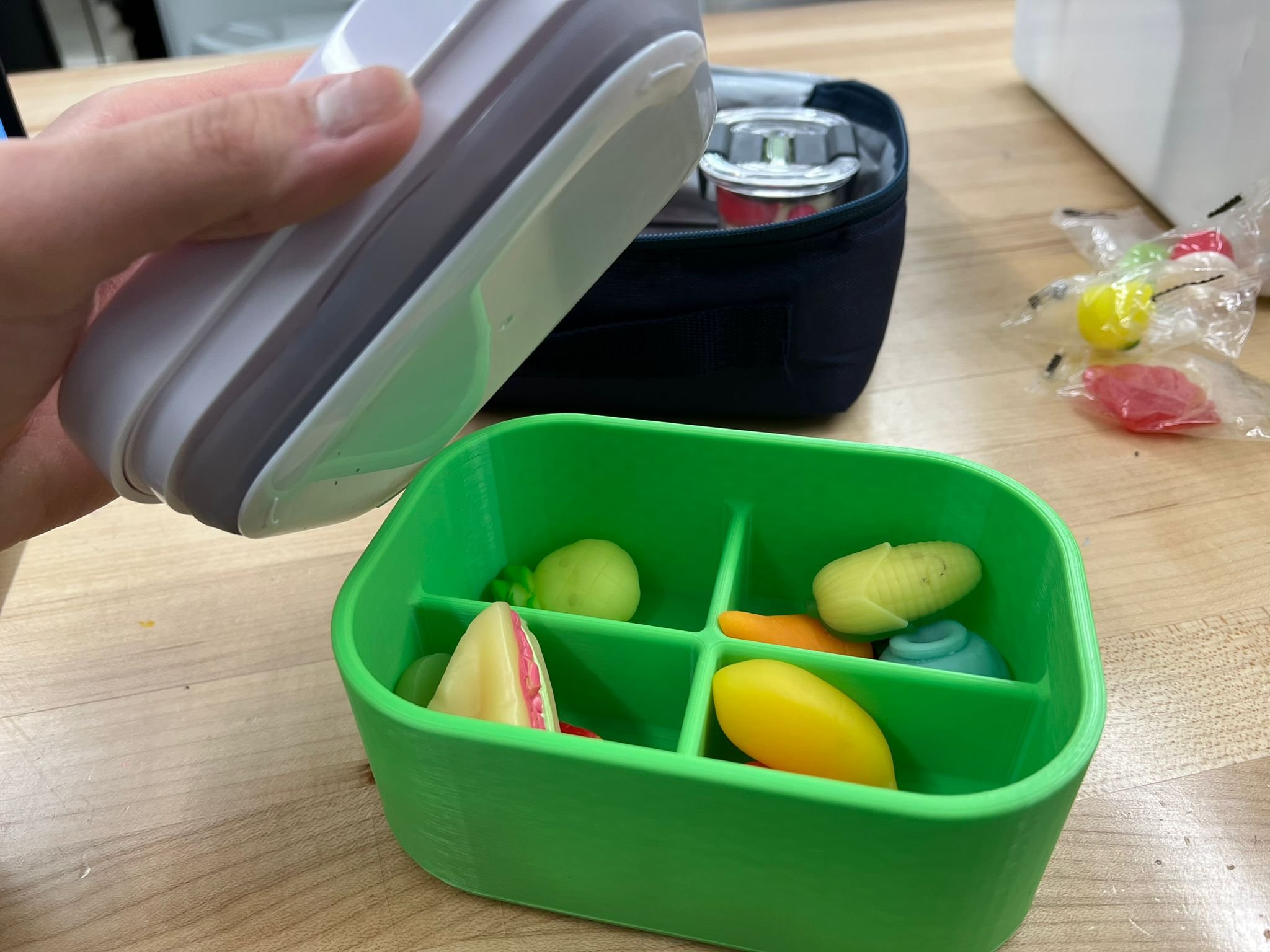

For the next design, we focused on adding in extra factors to add to the educational value. We added in more squishy food toys, we made sure to have a representative sample of different colors and food groups to allow children to sort the foods as they identify them. We also began to develop the idea of containers in the box. Something REACH mentioned was that children also have difficulty operating food storage containers, we remedied this by having the foods be placed into containers. This gave the child the opportunity to practice opening the containers, as well as placing them back into the lunchbox once play had concluded.

We decided to create a lunch box toy that would cater to these needs. The first prototype we designed focused on the core ideas of the problem. We created a box that would house squishy food toys, while the only way to open the box was to operate a zipper. The squishy toys inside the box provided the child with incentive to get inside the lunch box, allowing them to have fun as they practice.

For our final design we refined all the ideas we had had previously. We modified the zipper to be longer, allowing for the child to better grip the zipper as they pull it around the lunchbox. We got three different containers of several different shapes and opening mechanisms to ensure the child learns how to operate many different forms of fasteners. We placed clear dividers into the larger container to provide optional separation for the child’s sorting, as seen in the graphic below.

Testing & Validating

On our latest trip to REACH we received great amounts of positive feedback from the therapists and the children. Most children played with our toy in a way that was intended and allowed them to work with the therapist to receive the educational benefit of the toy.

We frequently found that the toy was used as a way for the children to practice speech, as each of the squishy foods required a different set of phonics to say. This was an aspect of our toy that we did not anticipate, allowing us to introspect even further to the customizability of Lunch-Time Fun-Time—an aspect that the therapists love as well.

We conducted our performance testing based on metrics that we predetermined for the Lunch-Time Fun-Time. We found that changes needed to be made for the easy to clean metric, as our design for the pop container made it unable to be washed with warm soapy water.

Through further testing we determined that although we may add protective filets to best ensure the integrity of the box, it was still best that only sanitizing wipes be used to clean it. Through this testing process we learned that it is not feasible to score a perfect score on every metric, as by making the box waterproof, the price of manufacturing would greatly increase, overall lowering the toy’s ability to meet the low-cost metric.

Our toy was required to pass several ASTM tests to ensure it was safe when given to children. For the drop test, our glass pop container broke, prompting us to do a redesign so that we could maintain the same pop fastener whilst improving upon durability by printing it out of TPU.

Both the redesigned pop container and the rest of the components passed both the torque, tension, and sharp edge tests, indicating that our toy meets these key ASTM standards.

Takeaways

I will forever cherish this project. It clarified to me why I do what I do and has acted as a focus for the rest of my time as a designer.

This was my very first project at university, and like any over-zealous freshman engineer would be, I was excited to over-engineer. Stuffing whatever I made full of the finest PETG and the biggest microcontroller I could get my hands on.

But this project did not start off as hi-fi. It started as cardboard, moving to slightly better cardboard and settling as a store-bought lunch box, with (mostly) store-bought food containers, with store-bought squishy toys.

A part of me was disappointed. I felt as though I could have done better. Surely, I could have done something to raise the technical level of the project.

But when we handed the toy over to the kids, they were ecstatic. One child hugged the box and told us it was his favorite and that he wanted to keep it forever.

This moment validated how impactful good design is and hammered in the adage “Keep it simple, stupid!” Whilst CAD was helpful for fine tuning, the bulk of the project was able to be achieved through cheap parts from Walmart.

As fun as it would be to make every project a Rube-Goldberg machine. My job is to create something that will truly solve a problem. Engineering is my chosen passion to attempt this, and design is how I hope to make it a reality.